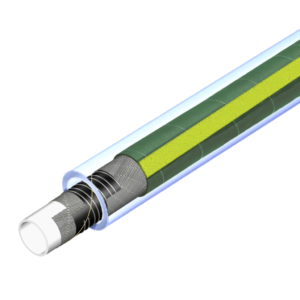

Industrial Hose

Industrial Rubber

Industrial Rubber refers to rubber materials and products designed specifically for industrial applications. These products are known for their durability, flexibility, and ability to withstand harsh environments. They play a critical role in various sectors, including manufacturing, construction, mining, and transportation.

Types of Industrial Rubber

- Natural Rubber (NR): Offers excellent elasticity and resilience, often used in conveyor belts and seals.

- Synthetic Rubber:

- Nitrile Rubber (NBR): Resistant to oils and fuels, commonly used in seals and gaskets.

- EPDM (Ethylene Propylene Diene Monomer): Ideal for weather-resistant applications like roofing and outdoor seals.

- Silicone Rubber: Withstands extreme temperatures, used in medical and aerospace industries.

- Neoprene (CR): Resistant to oil, chemicals, and weather, used in hoses and gaskets.

- Viton® (FKM): A high-performance rubber for extreme chemical and temperature resistance.

Applications

- Sealing and Insulation: Gaskets, O-rings, and seals in machinery and pipelines.

- Vibration Control: Rubber mounts and pads to absorb vibrations and noise.

- Conveyor Systems: Rubber conveyor belts for transporting materials in manufacturing and mining.

- Protective Coatings: Linings for tanks, pipes, and industrial equipment.

- Hoses and Tubing: For fluid and gas transfer in high-pressure and high-temperature environments.

- Belting: Heavy-duty rubber belts for industrial machinery.

Properties of Industrial Rubber

- Durability: Can withstand heavy loads and wear over time.

- Resistance: Excellent performance against chemicals, oils, abrasion, and extreme temperatures.

- Elasticity: Maintains flexibility under stress or compression.

- Waterproofing: Used in sealing applications to prevent leaks.

Key Industries Using Industrial Rubber

- Manufacturing: For machinery components and conveyor systems.

- Construction: In roofing, expansion joints, and soundproofing.

- Automotive: Tires, belts, and vibration dampers.

- Mining and Oil & Gas: High-pressure hoses, gaskets, and conveyor systems.

- Aerospace: High-performance seals and thermal insulation.

Benefits

- Customization: Can be molded or extruded into specific shapes and sizes.

- Longevity: Designed for long-term industrial use under challenging conditions.

- Cost-Effective: Durable and efficient, reducing maintenance and downtime.

Reviews

There are no reviews yet.